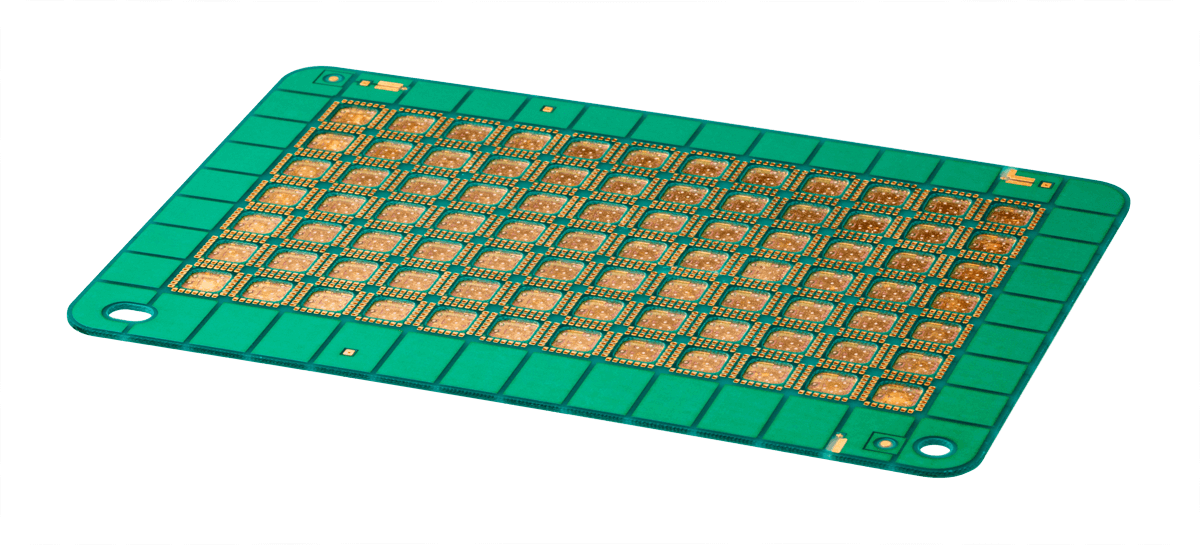

High Modulus/Low CTE PWBs

Warp can be remarkably reduced because of the small XY-axis expansion coefficient and high coefficient of elasticity.

An environment with a large temperature change may cause cracks in solder joints due to differences in thermal expansion coefficients, which reduce connection reliability. To prevent this, the thermal expansion coefficient of the PWB must be reduced.

The thermal expansion coefficient can be reduced to as low as that of alumina ceramics or silicones.

Principal use

Servers / Routers / Measuring Instruments / Communication Equipment / Semiconductor Packages

Technology / Composition

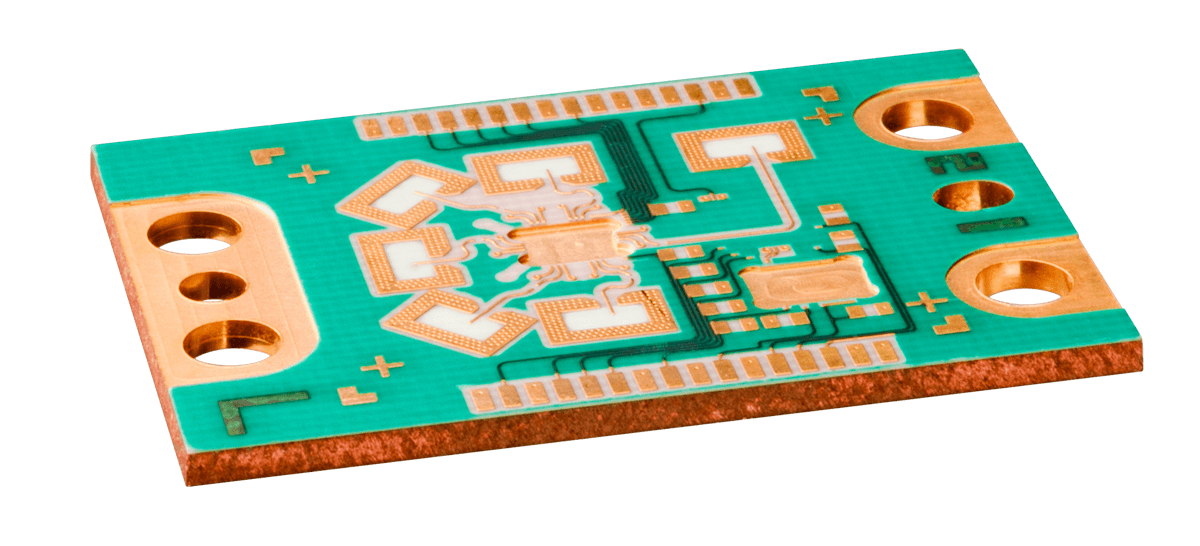

High-Frequency PWBs

High-quality and high-speed signal processing in high-frequency signal circuits can be supported by combining our manufacturing technology with high-frequency materials for low dielectric constant, low dielectric tangent, and low transmission loss processing.

Principal use

Antennas / Radars / Automotive Sensors / Power Amplifiers

Technology / Composition

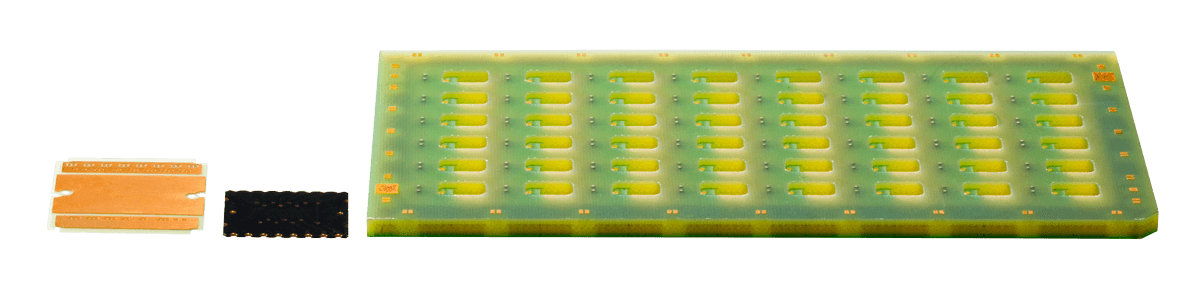

Thin/Thick PWBs

Demand for thin PWBs has increased, mainly for mobile purposes.

We can supply thin PWBs that reduce warping during chip installation.

To install heavy parts or large chips on PWBs, we can supply thick PWBs that are made of highly elastic or low thermal expansion materials.

Principal use

Low-Profile Modules / Mobile Terminal Apparatus / Medical Equipment

Technology / Composition

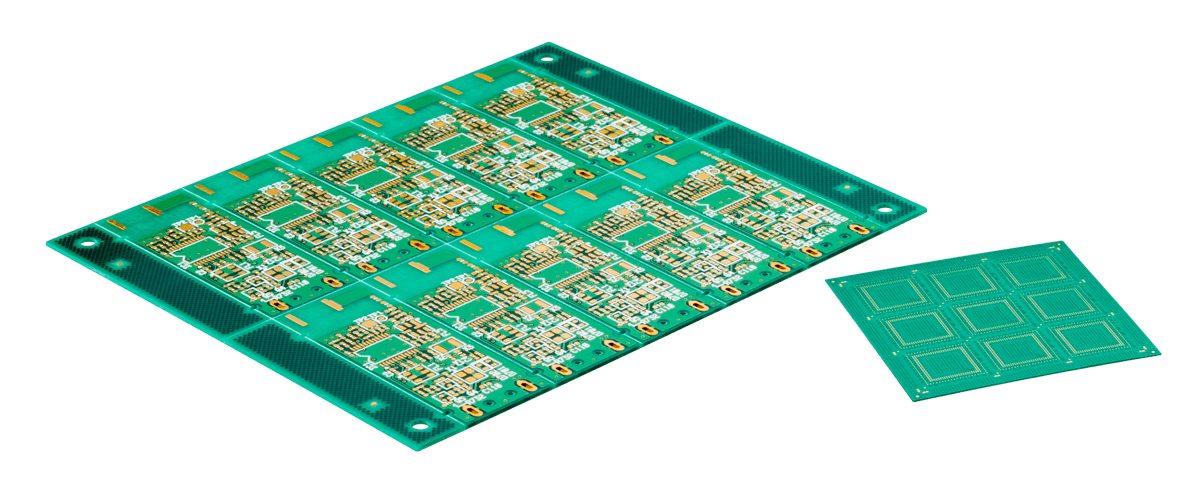

Double-Sided/Multi-layer PWBs

This PWB is made of conductive layers that are connected via copper-plated through-holes.

From general-purpose to special-purpose products, you can achieve both low cost and high quality by selecting optimal materials to suit your purposes.

Principal use

Computers / Industrial Machinery / Measuring Instruments

Technology / Composition

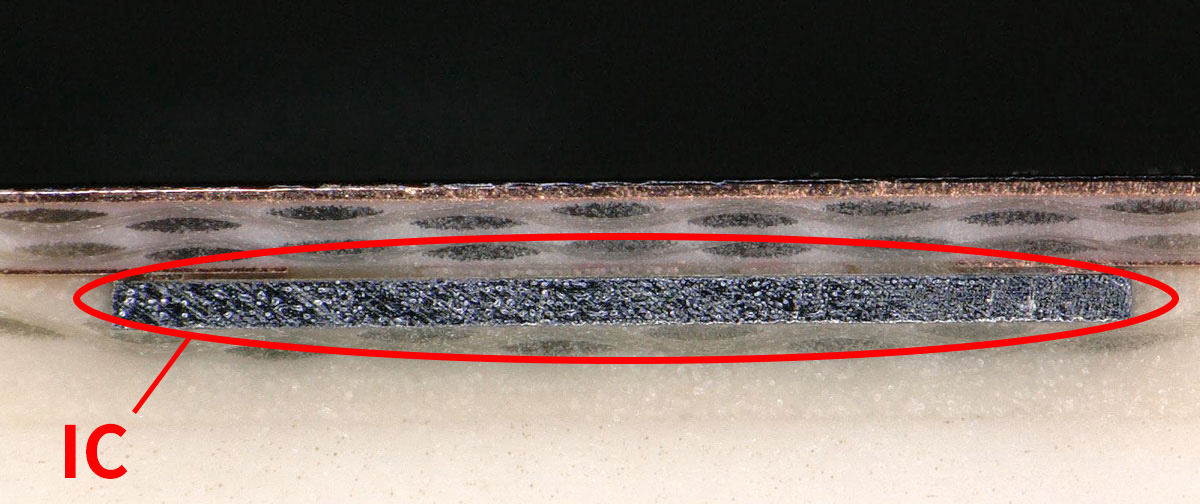

Embedded Component PWBs

Reliable products can be manufactured by embedding and laminating components.

In addition, passive components can be embedded in multilayer structures to supply high-density products.

Principal use

High-Frequency Components